I used energy this weekend by walking, jogging, and eating, which is also known as mechanical energy. I also used energy by using electricity. I used thermal energy when I was making tea by boiling a kettle. I transferred energy when I was playing soccer. The energy from my moving foot was transferred to the soccer ball when I kicked it.

Category: 6th Grade

What is Energy?

Energy is the capacity to do work. Energy can only be stored or transferred and cannot be destroyed or created.

Tech #11 – Finishing my Flashlight

In tech, I finally started working on soldering my battery, wires, and LED light together. First, I soldered my shortest wire to my battery. Before you solder, you have to make a hook on the end of the wire with a tool. Then, you attach the hook to the battery. I cut a piece of soldering wire and heated up my soldering iron by placing it on the object I was going to solder for five seconds. Then, I took my soldering wire and I put the soldering iron on top of it, so the soldering wire would melt and harden. After that, I soldered my other wire to my switch. This was the hardest part for me to solder because there was barely any space to put my soldering iron in. Eventually, I finished and moved on to soldering my wire to my LED light.

On my LED light, there is a long leg and a short leg. The longer leg was the positive side and the shorter leg was the negative side. I had to bend the longer leg and make it as far apart as possible from the other leg because the flashlight won’t work if both wires are touching. I soldered my positive wire to the positive leg on the LED light. Finally, I had to solder all of the pieces together to connect them. After I completed that, I drilled a hole in the middle of my flashlight for my switch. Then, I put everything I soldered into the right places of my flashlight. I needed to put a cover on my switch to protect it from water. I put all my pieces together and tried it out, and luckily, it worked. This project was really fun and I’m so excited to do something new.

Tech #10 – Putting my Flashlight Together

I didn’t write Charlotte there. It just came with the pipe.

This is the hole that the LED light will shine through.

After I have drew my sketch, I started making the outside of my flashlight. The materials I needed to make the outside of my flashlight are a straight pipe, two round caps, a saw, and a drill press. A drill press is a tool that can make holes through tough materials. The drill is similar to a drill, but you don’t have to hold the tool in your hand.

First, I made my straight pipe. I did that by getting a straight pipe, and cutting it to the measurement I wanted it to be cut. I used a saw to cut the straight pipe until the pipe was 6 1/2 inches. Then, I got two round caps. I got one round cap and drilled a hole in it with the drill press. The round cap with the hole is where the LED light will shine through. The other round cap without the hole will be put on the other side of the straight pipe. After I assembled my flashlight, I colored both round caps silver. I colored the two round caps with a silver paint marker. The next step is to solder the three wires, battery, and LED light.

Tech #9 – Designing my Flashlight

After I finished measuring the pipes, I started designing my flashlight. First, I though about what type of pipes to use in my flashlight. I decided to use a straight pipe, two connectors, a switch, and two round caps for the outside of the flashlight. For the inside of my flashlight, I have three wires, an LED light, and a battery. Then, I sketched my design on a separate piece of paper. I drew everything I wanted to use to make my flashlight in my sketch. After I did that, I started labeling each part of my flashlight.

Once that was finished, I drew my final sketch of my flashlight on graphing paper. The difference between this sketch and the one I did before is that I actually have to draw it to scale. By that I mean drawing the flashlight using the measurements. In the sketch, I had to draw the outside and inside of my flashlight. On the inside of my flashlight, I drew three wires, one battery, and one LED light. Since I’m finished with drawing my flashlight, my next step is to make the flashlight.

Tech #8 – Measuring Pipes

For the past few days, we’ve been working on measuring different types of pipes. We got a piece of paper that showed four different objects. Two were pipes, one was for connecting pipes, and one was for closing the open parts of the pipe. There were arrows going around each object. We had to put the measurements of the pipes where the arrows were. We measured the two pipes using a ruler, and wrote the measurements down next to the arrows. Then, we drew the pipes on graphing paper from scratch. For this part, we had to rely a lot on the piece of paper where we put all of the measurements for the pipes.

When you finish measuring the first pipe, you have to measure the second one. I repeated everything I did for the first pipe. I measured the pipe and drew the pipe on a separate piece of graphing paper. After you finish measuring and drawing the two pipes, you’re ready for sketching your design for your flashlight. I’m so happy that I finished the measurements and I’m so excited to start sketching my design for my flashlight.

Tech #7 – Flashlights

In tech, we discussed the story of the soccer team that got stuck in a cave. After we talked about that story, it lead us to our new project, which was to build a waterproof flashlight. I started brainstorming ideas for my flashlight. For my flashlight, I want to use pipes, connectors, a switch, and a light. A connector is something that connects the pipes together. I’m so excited to build my flashlight.

Tech #6 – Switches

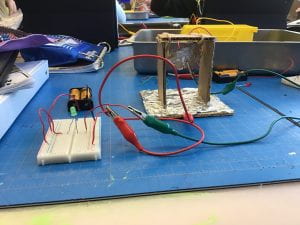

In tech, we built switches. The goal was to make a switch that lights up an LED light. For my switch, I used rubber bands, cardboard, and tinfoil. I used hot glue to stick everything together. The tinfoil was the most important part of the switch because that’s what would light up the LED light. When you touch the two pieces of tinfoil together, the LED light lights up. This was really fun to make.

Tech #5 – Soldering our Designs

I have finally finished my pendant. It took a lot of time and effort, but I’m very proud of myself for completing it. During my last blog post, I was still working on the design for my pendant. I designed it by bending metal wires to make it look like my design. After I finished doing that, I had to solder it together. I soldered it by using a soldering iron and a soldering wire. A soldering iron is an iron that’s very hot, and is used to connect the wires all together. A soldering wire is the wire that is melted by the soldering iron. The soldering wire acts like a glue that sticks all the wires together.

First, I cleaned my soldering iron. Then, I let the soldering iron touch the place where I wanted the wires to connect. I did that for ten seconds to heat up the soldering iron. Next, I got my soldering wire and put it in between the two wires I wanted to connect. After that, I put the soldering iron right on top of the soldering wire, which made the soldering wire melt. After a few seconds, the melted wire hardened. I repeated these steps until all of my pieces were connected. When the pendant cools down, I carefully removed the pendant from the piece of tape it was on. After that step, I was finally finished with my pendant. My pendant didn’t come out perfect, but this was so fun to do and I hope I get a chance to do it again.

Tech #4 – Pendant Designing

In tech, we started working on our actual designs fro our pendants. Before we started making the pendants, we had to brainstorm designs on paper. The design that we chose is supposed to act as a guide. You make the design with metal wires by using a special type of tape and you stick it on top of your design. Next, you peel off the other side of the tape and stick the pendant onto it. Then, start making the design for you pendant.

For the pendant design, you get a metal wire and start shaping the wire so it eventually looks like the design you made. When you have the pieces of your design, you’re supposed to stick it on the tape where the inside of the pendant is. When the pendant is complete, you solder all the pieces together. I’m not up to that part yet, but I’m still on the designing part. This is really fun and I’m so excited to solder all of the pieces together.

Recent Comments